Posi-STRUT Truss System

Web Sizes, Layout and Service Clearances

Posi-STRUT Web Sizes

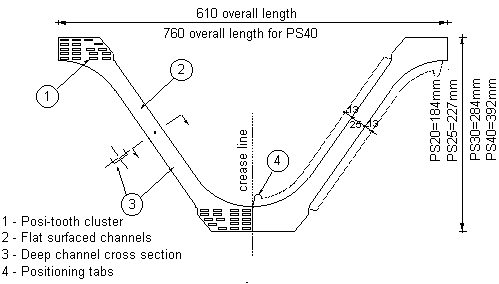

The GANG-NAIL Posi-STRUT is a V-shaped metal web stamped from 0.91mm ASTM A446 Grade A (yield strength 230MPa, ultimate strength 310Mpa) steel with a Z275 galvanised coating. Posi-STRUT is available in four depths or sizes: PS20, PS25, PS30 and PS40.

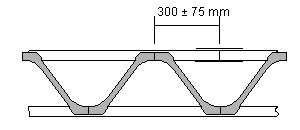

The modular length of Posi-STRUT is 610 mm (760 mm for PS-40), which can be split in half at a crease in the middle to form two 305 mm (380 mm for PS-40) half webs. The various depth of sections are as follows:

Web Size | Web Depth | Weight per web | Truss Weight(90x45 chords) | No. of teeth(ends/crotch) |

| PS-20 | 184 mm | 0.24 kg | 4.85 kg/m | 14/28 |

| PS-25 | 227 mm | 0.29 kg | 5.02 kg/m | 18/36 |

| PS-30 | 284 mm | 0.37 kg | 5.28 kg/m | 20/40 |

| PS-40 | 392 mm | 0.50 kg | 5.72 kg/m | 20/40 |

Web Layouts

The following rules should be followed when laying out the webs:

1. Always start detailing from the supports and work inwards towards the centre of the span.

2. The first web from a support always meets the top chord, not the bottom chord.

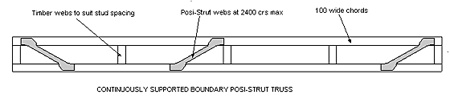

3. A timber web is required at each support and each strongback location.

4. The strongback should be hard up against the top chord. On-site the strongback should be clamped against the top chord and nailed. To achieve this the adjacent Posi-STRUT web should meet the bottom chord at the strongback location.

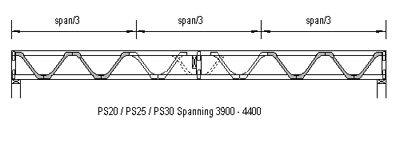

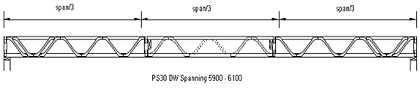

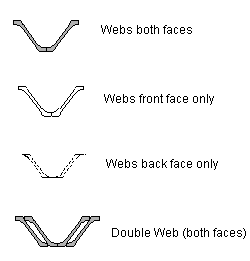

5. The number of webs required is reduced over the middle third of the truss. This is achieved through staggering alternating webs at the middle of the span. Webs on both faces of the truss are required for the outer third of the truss span, for the inner third there must be a web on at least one face of the truss, with adjacent webs on alternate faces.

6. The requirement for only one face of the middle third of the truss to have a web covering it allows adjustment to be made to suit the span of the truss.

7. The maximum gap between adjacent webs in the outer third of the span is 3mm.

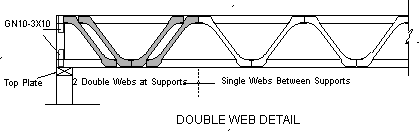

8. Where double webs are called up in the selection tables (as bold and shaded area on chart, and/or followed by 'DW' in the truss code) the double webs are required at the vicinity of support locations as shown on the double web detail.

Splicing

Chord butt splices are pressed symmetrically across the joint on both sides, on the wide faces of the timber chord. These splices are normally applied before assembly as a truss, and should be positioned away from web panel points. Where both top and bottom chords are spliced, splices should occur at opposite ends of the truss.

The ends of the chords to be spliced should be in contact in at least one point, with any gaps no greater than 2 mm. The splice plate size is as follows:

| Chord Size | Splice Plate Size(No.1Fr, F5, MGP10, TF9) | Splice Plate Size (F8, MGP12) |

| 70 x 45 | GN10-7x17 | GN10-7x22 |

| 90 x 45 | GN10-7x22 | GN16-7x27 |

| 90 x 35 | GN10-7x17 | GN10-7x22 |

| 140 x 45 | GN10-14x17 | GN10-14x22 |

| PS-20 | PS-25 | PS-30 | PS-40 | |

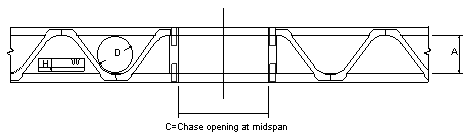

| A (mm) | 127 | 158 | 212 | 322 |

| D (mm) | 120 | 152 | 203 | 280 |

| C (mm) | 500 | 500 | 500 | 500 |

| H (mm) | W (mm) | |||

| 50 | 280 | 311 | 342 | 494 |

| 75 | 200 | 260 | 304 | 460 |

| 100 | 120 | 209 | 260 | 416 |

| 125 | - | 158 | 215 | 377 |

| 150 | - | 69 | 177 | 338 |

| 175 | - | - | 139 | 300 |

| 200 | - | - | 76 | 258 |