Manufacture

Timber Specification

Radiata Pine machine stress graded to AS1748 (F5, F8, MGP10 or MGP12) Or Radiata Pine No.1 framing in the place of F5

Or Douglas Fir No.1 framing in the place of F5

Treatment - TPA Specification H1, or as specified in NZS 3602

Manufacturing Tolerances

The following manufacturing tolerances apply to the fabrication of Posi-STRUT trusses:

Camber

Midspan camber is normally set at Span/1000 but not greater than 6mm for Posi-STRUT floor trusses; Span/280 but not greater than 30mm for Posi-STRUT purlins; and Span/350 but not greater than 20mm for Posi-STRUT rafters. The camber should be reduced for trusses spanning less that the maximum span.

The following are some expressions of camber in millimetres for various spans:

.

Span/1000(floor) Camber Span Span/280(purlins) Span/350(rafters) 4000 14 11 4 5000 18 14 5 6000 21 17 6 7000 25 20 6 max 8000 28 20 max - 9000 & over 30 max 20 max -

Handling & Storage

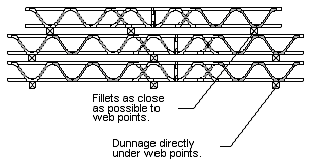

Posi-STRUT trusses should be strapped and stacked upright with the bottom chord clear off the ground and on level fillets or dunnage directly underneath web points. Trusses may be stacked on top of each other with fillets aligned as closely as possible to web panel points.

Posi-STRUT trusses should not be left exposed to weather for extended periods of time without adequate protection. If covered, adequate air circulation should be ensured around the trusses.

Care should be taken when handling the truss not to bend, collide, twist or drop. Handling should be confined to the timber chords, and no weight should be applied to the metal webs which could cause buckling.

Any truss damaged in transport or handling cannot be repaired on site without the advice or approval of the manufacturer.